Brass sealing ???

by Renee

(Winthrop, MA)

I've recently got into hand stamped jewelry. I've been using stainless steel and brass blanks because they are fairly inexpensive, especially compared to sterling silver! My problem is that the brass is so darn soft! I just received a Lortone 3A tumbler and its running for the first time to attempt to polish up a few blanks. My problem is that I love the look of a mirror like polish on the brass. I was able to achieve this by using a dremel and polishing compound. But the second I touch anything to the brass to wipe off the excess compound, the brass gets little fine scratches on it. I even used my camera cloths I use on my $1800 camera lenses and it still gets fine scratches!!! It's so aggravating.

So, I've given up on the mirror finish and resorted to a brushed brass finish. It's fine but it scratches so easily. By the time I get my crystal hung and the jump ring through the hole, there are scratches all over it. Can you recommend any way to finish brass? My hardware store associate/ jewelry maker told me to spray it with a clear coat to resist tarnish and scratches but I'm finding those to also scratch up with just a light sweep of my fingernail. I bought clear Rustoleum and it seemed to work ok but had to sit there for 3 days. My best try was with Sally Hanson diamond nails clear coat but it dried too fast and with that little brush, it wouldn't level out so it looked bumpy. The scratch resistance was fabulous though. Please help!

Thank you so much for this awesome site and information.

Renee.

Stacy's Answer:

Hi Renee!

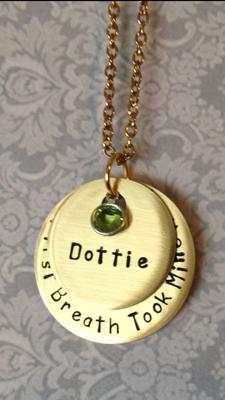

The pendant in the photo looks like it has a very nice satin finish and I don't see any scratches! Nice stamping job and I love the fonts!

Brass is usually pretty tough and I've never had a problem with it scratching up as yours seems to be doing. Stainless steel is very tough...and hard! I think you may have a cross-contamination problem. Because brass is a non-ferrous metal and much softer than Stainless steel which is a ferrous metal, different tools are recommended when working with the metals. Cross contamination can be a problem when switching between different metals regardless of what they are, but especially when going between ferrous and non-ferrous ones.

As for the lacquer clear-coat.......I prefer Permalac Lacquer or Clear Guard lacquer by sculpt Nouveau. Before you lacquer, make sure that your metal is uber clean. To quickly accomplish this, simply dip the metal in acetone (fingernail polish - NOT the non-acetone kind) and let dry. Then dip or brush-on the lacquer. Because these lacquers are not water soluble, a little extra care must be taken. I use a blow-dryer to quickly set the lacquer and that helps to prevent any moisture that may be even thinking about coming between the metal and the lacquer from occurring. If moisture is present (I live in the humid tropics, so moisture is a common problem), then the lacquer dries milky. Bad!

Are you using a polishing cloth, buffs or tools that you've used on the stainless steel? Fine stainless steel particles embedded in a buff, etc. will scratch the much softer brass. Try using different tools for your stainless steel and other metals like silver, brass, copper, etc. ESPECIALLY when finishing them!. Be aware also, that striking really hard metals with softer tool steel like your letter punches are made from, can damage your punches by eventually flattening them out. Metals all have their own unique properties so-to-speak and some just don't play well with others! If you treat them in the same way you can have disappointing results.

Return to Tumble Polishing Q & A.